Densen Customized Stainless Steel Swim SPA and Swimming Pool Accessories

Basic Info.

| Model NO. | OEM |

| Surface Roughness | Ra1.6 |

| Machining Tolerance | +/-0.15mm |

| Standard | GB |

| Certification | CE, ISO 9001:2008 |

| Occasion | Bathroom, Gym, Garden, Playground, 10000 Piece/Pieces Per Month Stainless Steel Swim |

| Transport Package | Normal Package |

| Specification | Densen Customized |

| Trademark | OEM |

| Origin | China (Mainland) |

| Production Capacity | 10000 Piece/Pieces Per Month Stainless Steel Swim |

Product Description

Densen customized Stainless Steel Swim Spa and Swimming pool accessoriesWe have professionals to solve your questions, please contact us directly!

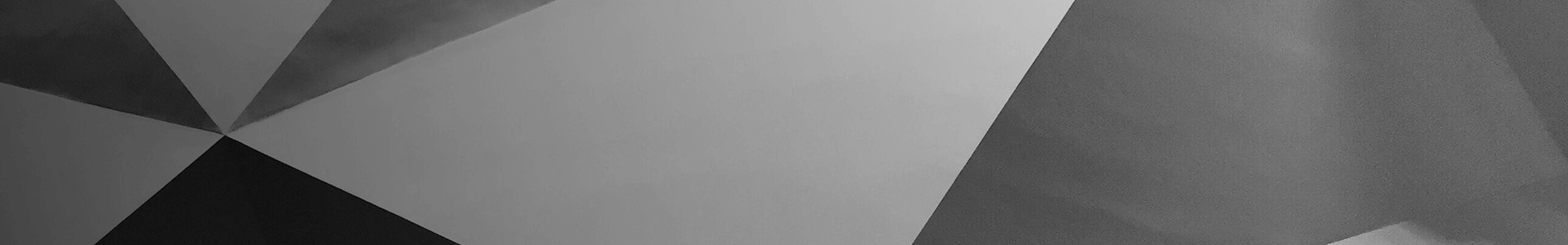

Description | Swimming pool accessories |

Application | Water sport,Swimming pool |

Processing | Investment casting |

Material | Copper ;Stainless steel (304/316/304L);Aluminum |

| Weight Ranges | 0.05-100kg |

Tolernace | Controlled by ISO 8006 CT4-6 |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

Quality Control | Material, Dimension,Performance,inside defects,Balance test |

Standard | ASTM,DIN,JIS,ISO,GB standards |

Products show:

Declaration:

Products shown herein are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within Densen group of companies.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

Company Information

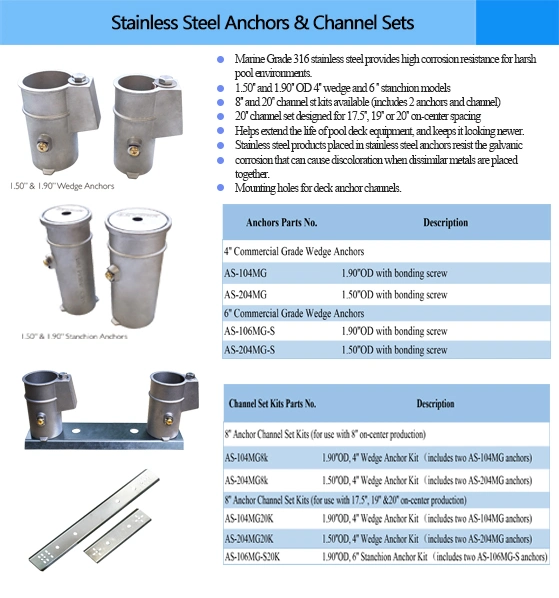

Densen Group Architecture:

Shenyang New Densen Casting and Forging Company is the sales company of Shenyang Densen Group of Companies. Features of New Densen simply summarized as below:

1. Trusted supplier of steel, iron & non-ferrous components;

2. Extensive documented quality program in place.

3. Castings, forgings, stampings, machining, welding & fabrication services.

4. 9 related factories, over 50 joint-venture sub-contractors.

5. 25+ years of manufacturing experiences, 10+ years of exporting experience

6. 100% of products sold to overseas customers.

7. 50% of customer base is forturne 500 companies.

Processing support

Casting Service:

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify.

New Densen offers multiple investment casting, sand casting, permanent casting, die casting, low pressure casting, ESR casting, lost foam casting, etc. Material can be handled include steel, iron, non-ferrous. Single component weight range is from 0.01Kg to 150 tons separately.

Forging Service:

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. New Densen offers open die forging, closed die forging and ring forging services. Material can be steel, iron and non-ferrous. Material can be handled include steel, iron, non-ferrous. Single component weight range is from 0.1Kg to 50,000Kgs.

Stamping Service:

Stamping (also known as punching) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape.

New Densen-XBL has more than 60 sets stamping equipments, is the designed supplier for several famous bands automotive companies, has the full ability to offer whole processes from blanking, stamping, welding, to electrostatic spraying for worldwide customers.

Welding & Fabrication Service:

Welding Frabrication is the fabrication process of metal structures by cutting, bending, then assembling the components together through welding

New Densen offers manual arc welding ,laser welding and robot welding etc. UT, MPT,RT,PT all are available used for inspection, WPS &PQR (Welding Process Specification& Procedure Qualification Records) before production is available under clients' requirement.

3rd Party Inspection:

New Densen worked as 3rd party inspection center besides its sister factories or sub-contractors' self inspection, Offers process inspection, random inspection and before delivedry inspection services for material, mechanical, inside defects, dimentional, pressure, load, balance, surface treatment, visual inspection and test. Weekly project follow-up report together with pictures and videos, full quality inspection documentation available.

New Densen also designed as 3rd party inspection representative for several customers when their products made by other suppliers.

Contact us